Nature as a Factory.

We don’t manufacture packaging. We grow it.

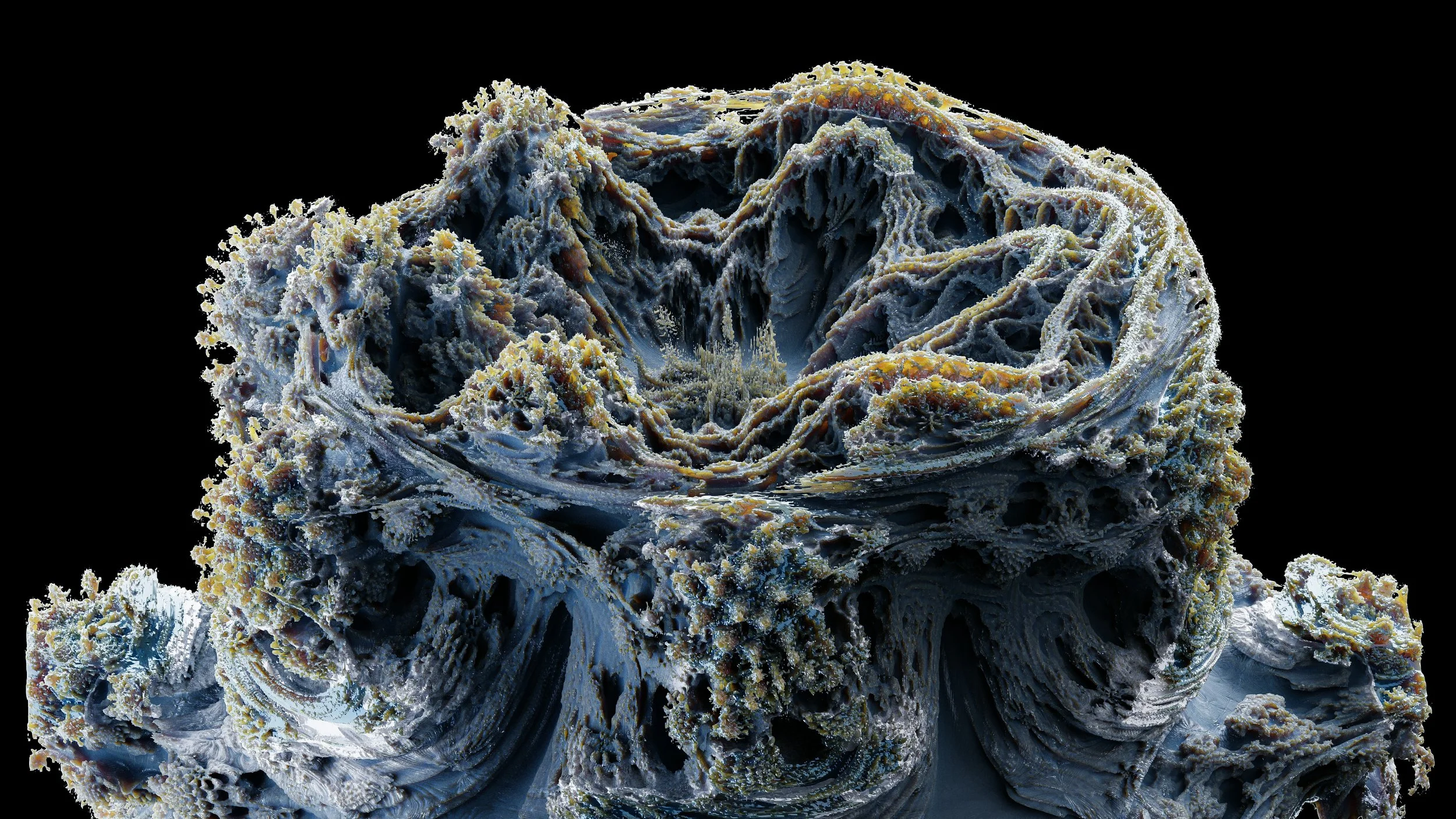

How it Works

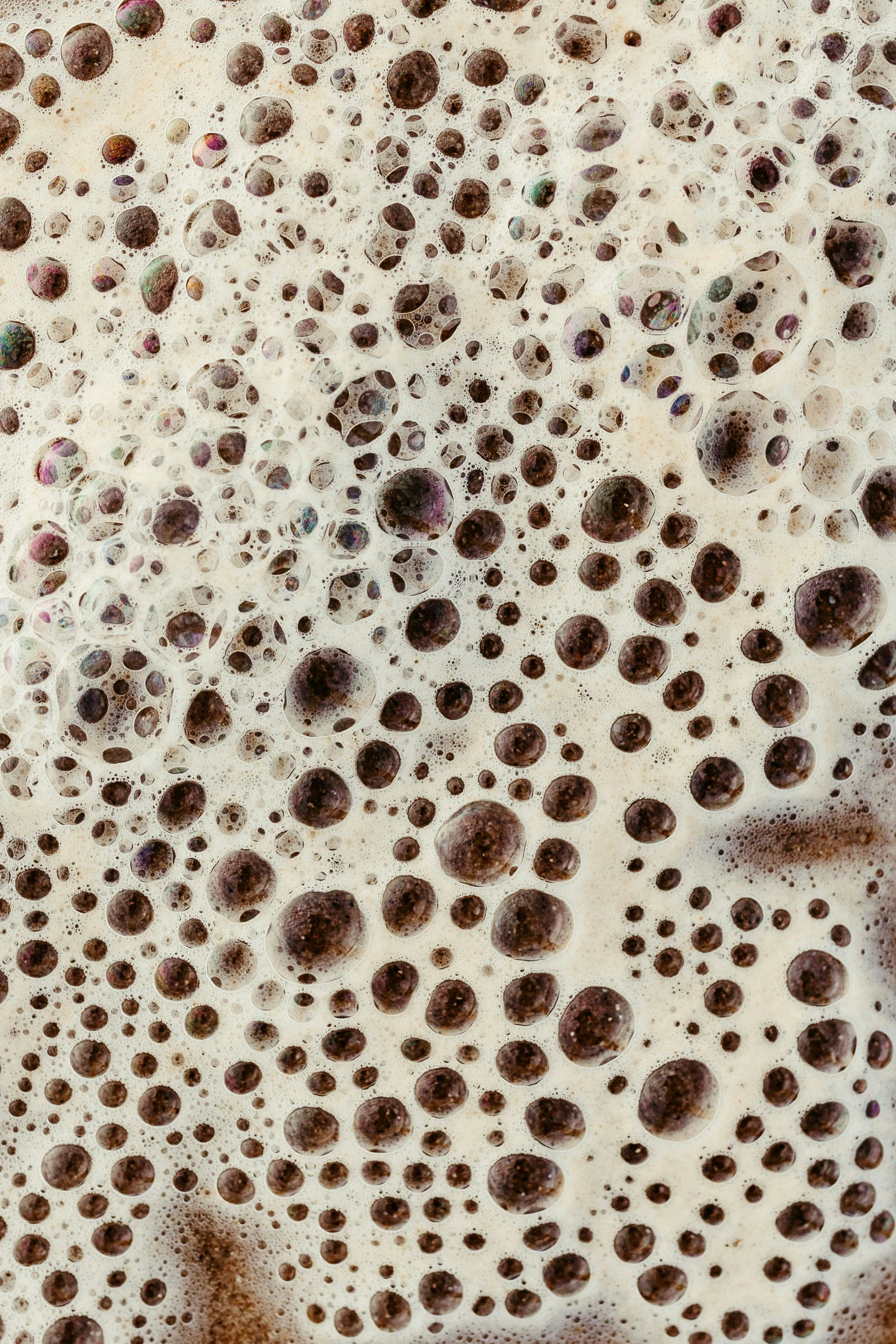

1. Waste in.

We start with what others throw away: agricultural byproducts, cardboard scrap, and textile fibers. These waste streams are the foundation of our materials.

2. Mycelium Grows

Mycelium — the root system of fungi — feeds on this waste. As it grows, it creates dense networks that bind fibers into strong, lightweight structures.

3. Packaging Out

We mold this growth into protective shapes, delivering packaging that performs like Styrofoam: durable, insulating, lightweight.

4. Back to Earth

When its job is done, our packaging composts naturally within weeks. No toxins, no microplastics, no trace.

Why It Matters

Scalable

Inputs are abundant and renewable.

Waste becomes resource. Packaging becomes soil.

Circular

Proven in electronics, retail, food, and logistics.

Industrial Performance

Every kilogram of Upto replaces Styrofoam and avoids its carbon footprint.

Climate Impact

A New Model for Materials

We call it Nature as a Factory. Instead of extracting oil and producing plastics, we feed waste to fungi and let biology do the work.

The result: packaging that protects products, people, and the planet.